1. Introduction

1.1 Purpose of the Manual

This manual outlines the essential safety and security policies and procedures for Sohar Energy and Investment. Our primary goal is to establish and maintain a safe working environment for all employees, contractors, visitors, and clients, minimizing risks and promoting well-being. The framework adheres to internationally recognized standards: ISO 45001 (Occupational Health and Safety) and ISO 9001 (Quality Management).

1.2 Scope of Application

The standards and procedures detailed herein apply universally across all Sohar Energy and Investment operations, facilities, and personnel, including permanent offices, temporary field sites, and remote work arrangements where applicable. This encompasses all activities conducted under the Sohar Energy and Investment banner that could potentially impact safety, health, or operational quality.

1.3 Management Commitment

Sohar Energy and Investment's leadership is fully committed to the principles outlined in this manual. We pledge to provide the necessary resources—including time, training, equipment, and financial support—to ensure its effective implementation and continuous improvement. This manual undergoes a formal review at least annually, or more frequently if significant operational changes or regulatory updates occur, ensuring ongoing relevance and compliance.

2. Safety Policies

2.1 Occupational Health and Safety (OHS) Policy

Sohar Energy and Investment is dedicated to a proactive OHS approach focused on:

- Preventing work-related injuries, incidents, and occupational illnesses through robust risk management.

- Fostering a culture of continuous improvement in our OHS performance and work environment.

- Ensuring full compliance with all applicable local, national, and international health and safety laws, regulations, and standards.

- Promoting active participation and consultation with employees on OHS matters.

2.2 Employee Responsibilities

Safety is a shared responsibility. All employees are expected to:

- Adhere strictly to all established safety rules, procedures, and guidelines.

- Report any observed hazards, unsafe conditions, near misses, or incidents immediately to their supervisor or designated safety personnel.

- Properly use and maintain all provided Personal Protective Equipment (PPE) as required for their tasks.

- Actively participate in mandatory safety training sessions and awareness programs.

- Contribute to a positive safety culture by looking out for colleagues and promoting safe practices.

3. Risk Assessment and Hazard Control

3.1 Hazard Identification

A systematic process is in place to proactively identify potential hazards across all work areas and activities. This includes routine inspections, job safety analyses (JSAs), employee feedback, and review of incident data. Hazards may include physical, chemical, biological, ergonomic, and psychosocial risks.

3.2 Risk Evaluation

Once identified, hazards are evaluated based on the likelihood of occurrence and the potential severity of consequences (injury, illness, property damage). This evaluation prioritizes risks, guiding the allocation of resources for control measures.

3.3 Control Measures

Sohar Energy and Investment follows the hierarchy of controls to mitigate risks:

- Elimination: Removing the hazard entirely.

- Substitution: Replacing the hazard with a less risky alternative.

- Engineering Controls: Isolating people from the hazard (e.g., machine guarding, ventilation).

- Administrative Controls: Changing the way people work (e.g., safe work procedures, training, signage).

- Personal Protective Equipment (PPE): Protecting the worker with PPE (last resort).

4. Emergency Preparedness and Response

4.1 Emergency Response Plan (ERP)

Sohar Energy and Investment maintains a comprehensive ERP detailing procedures for various potential emergencies, including fire, medical incidents, chemical spills, security threats, and natural disasters. The ERP is readily accessible to all personnel.

4.2 Evacuation Procedures

Clear evacuation routes and designated assembly points are established and marked throughout facilities. Regular evacuation drills are conducted to ensure familiarity and effectiveness. Procedures account for individuals requiring assistance.

4.3 First Aid and Medical Response

Adequate first aid supplies and trained first aid personnel are available at strategic locations. Procedures for obtaining professional medical assistance are clearly defined and communicated (see Appendices for contact details).

5. Training and Awareness

5.1 General Safety Induction

All new employees, contractors, and long-term visitors receive mandatory safety induction training covering company policies, key hazards, emergency procedures, and reporting requirements before commencing work.

5.2 Job-Specific Training

Personnel receive specific training relevant to the hazards and tasks associated with their roles, including safe operation of equipment, handling hazardous materials, confined space entry, working at height, and required PPE usage.

5.3 Refresher Training and Awareness

Regular refresher training and ongoing safety awareness campaigns (e.g., safety talks, bulletins, posters) are conducted to reinforce safety knowledge and address emerging issues or changes in procedures. Training effectiveness is periodically evaluated.

6. Compliance and Auditing

6.1 Legal and Other Requirements

Sohar Energy and Investment maintains a process to identify, access, and monitor compliance with all applicable OHS and quality-related legal requirements, industry standards (including ISO 45001 & ISO 9001), and other obligations.

6.2 Internal Audits

Regular internal audits are conducted to assess the effectiveness of the safety and quality management systems, verify compliance with this manual, and identify areas for improvement. Audit findings are documented, and corrective actions are tracked.

6.3 Management Review

Top management periodically reviews the OHS and quality performance, audit results, incident data, and overall system effectiveness to ensure its continuing suitability, adequacy, and effectiveness, and to drive continuous improvement.

7. Incident Reporting and Investigation

7.1 Reporting Procedure

All work-related incidents, including injuries, illnesses, property damage, environmental releases, security breaches, and near misses (events that could have resulted in harm), must be reported immediately to the relevant supervisor or safety personnel using the designated reporting forms/system.

7.2 Investigation Process

Significant incidents and near misses are investigated promptly to determine root causes and contributing factors. The investigation aims to understand 'why' the incident occurred, not to assign blame. Employee participation in investigations is encouraged.

7.3 Corrective and Preventive Actions

Based on investigation findings, corrective actions are implemented to address the immediate causes, and preventive actions are taken to prevent recurrence. The effectiveness of these actions is monitored and reviewed.

8. Continuous Improvement

8.1 Objectives and Targets

Sohar Energy and Investment sets measurable OHS and quality objectives and targets aligned with our policies and commitment to continuous improvement. Progress towards these objectives is regularly monitored and reviewed.

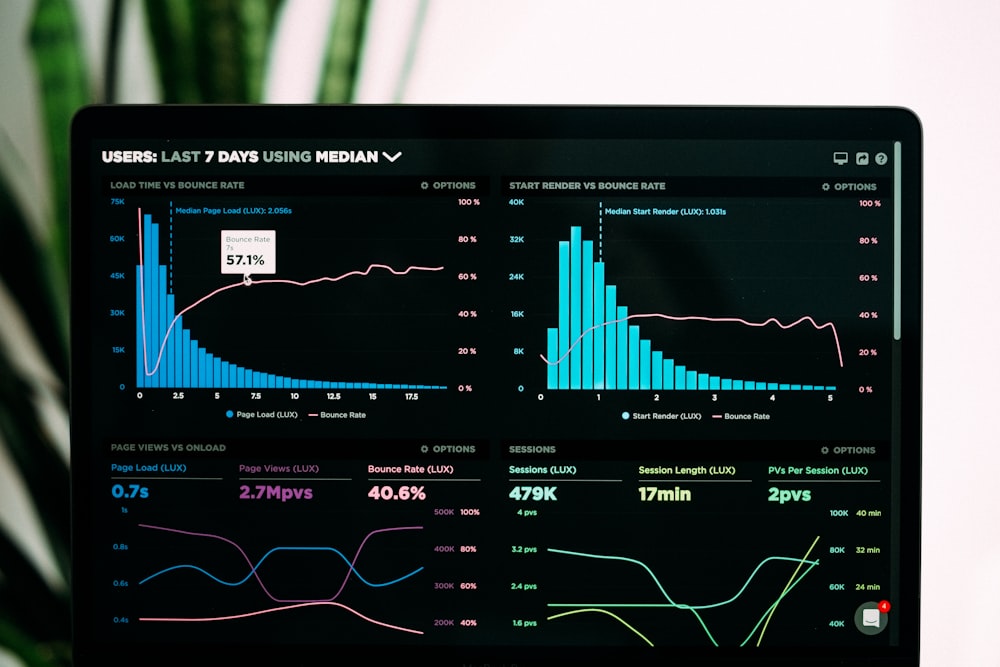

8.2 Performance Monitoring

Key performance indicators (KPIs) related to safety and quality (e.g., incident rates, training completion, audit findings, client feedback) are tracked and analyzed to identify trends and areas needing attention.

8.3 Feedback and Suggestions

Employees are encouraged to provide feedback and suggestions for improving safety, security, and quality through various channels (e.g., safety meetings, suggestion boxes, direct communication with supervisors/management). All suggestions are considered.

9. Appendices

This section contains supplementary information, forms, and checklists referenced throughout the manual. (Note: Actual documents would be linked or included here in a real-world scenario).

9.1 Example Safety Checklist Snippet (Monthly Site Check)

- Emergency Exits: Clear, unobstructed, signage visible? ☐ Yes ☐ No

- Fire Extinguishers: Correct type, charged, accessible, tagged? ☐ Yes ☐ No

- First Aid Kits: Stocked, accessible, items in date? ☐ Yes ☐ No

- PPE Stations: Sufficient stock, correct types available? ☐ Yes ☐ No

- Walkways/Aisles: Clear of trip hazards? ☐ Yes ☐ No

- Machine Guarding: In place and functional? ☐ Yes ☐ No

- Chemical Storage: Proper containers, labeled, segregated? ☐ Yes ☐ No

9.2 Key Emergency Contacts

- Internal Safety Department Lead: [+968-993-31453]

- Local Fire Department: [9999]

- Ambulance / Medical Emergency: [9999]

- Police: [9999]

- Sohar Energy and Investment Contact: [email protected] | +968-993-31453

Ensure these numbers are clearly displayed at relevant points throughout the facility.